Grounding System Types And Function Guide

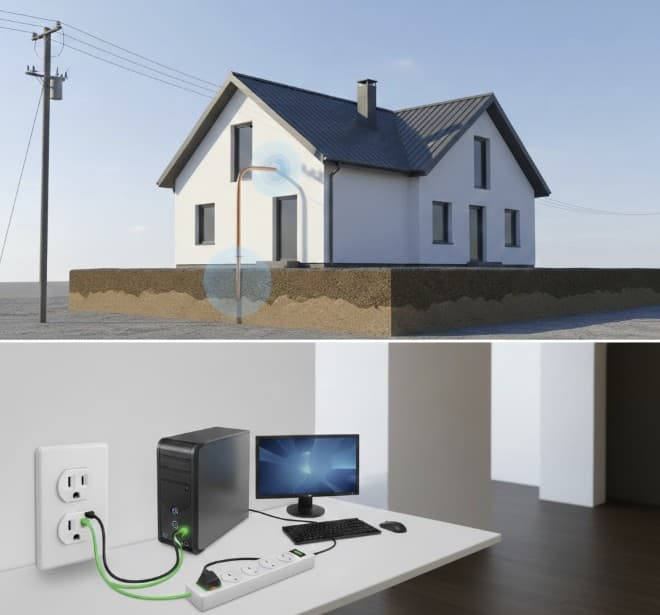

Electrical grounding ensures safety by providing a low-impedance path for fault currents, protecting equipment and personnel.

Research topics

Welcome to our guide on grounding systems! Understanding the different Grounding System types and their functions is vital to ensure the safety and efficiency of electrical installations. Grounding, or Electrical Grounding, provides a pathway for excess electricity to flow safely into the earth, thus protecting people, equipment, and facilities from electrical hazards.

What is Grounding?

Grounding is the process of transferring the immediate discharge of electrical energy directly to the earth through a low-resistance connection. This practice is essential to safeguard against shock hazards and electrical fires. It involves various Grounding Methods that, when properly implemented, ensure that the electrical systems are grounded effectively.

Types of Grounding Systems

There are several types of Grounding Systems that electricians and engineers use. The most common ones include:

- System Grounding: This type connects the electrical system's neutral point to the ground, setting a reference potential for the system.

- Equipment Grounding: This system connects non-current-carrying metal parts of equipment to ground, preventing electric shocks if there is a fault.

- Grounding Electrode System: Involves electrodes that are buried in the ground, providing a reliable return path for fault currents.

Grounding Techniques

Each type of grounding system relies on various Grounding Techniques which include direct burial of electrodes, the use of ground rods, plates, or buried parallel conductors. These methods are designed based on the specific Grounding Requirements necessary for different environments and equipment.

Grounding Installation

Successful grounding begins with proper Grounding Installation. This involves selecting appropriate materials—such as copper or aluminum conductors and electrodes—that resist corrosion. Adhering to Grounding Codes, like the National Electrical Code (NEC), ensures that installations are safe and compliant.

It's also crucial to ensure Grounding Inspection is part of the process to check for continuity, resistance, and appropriate connections every time a system is installed or altered.

Safety Grounding

One of the primary focuses of electrical grounding is Safety Grounding. By creating a path for fault current to flow, it minimizes the risk of electric shock to personnel and prevents potential damage to equipment. If electrical breakdowns happen, the grounded system will help in directing the fault current away, thereby avoiding the potential for fires or explosions.

Grounding Conductors

Grounding Conductors play an essential role in grounding systems. These conductors provide the path that allows electric charge to flow into the ground. Ensuring that these conductors are appropriately sized and installed is part of meeting the Grounding Requirements outlined by electrical codes and regulations.

Grounding Electrode Systems

The Grounding Electrode is a part of the grounding system and should be installed following the standards set by local codes. Common examples include ground rods, ground plates, and even concrete-encased electrodes. Facilities must analyze soil characteristics and moisture levels to ensure effectiveness.

Understanding Grounding Codes

Every state and local jurisdiction may have different Grounding Codes that they follow. Familiarity with these codes is essential not just for legal compliance but also for ensuring safety in electrical installations. Codes dictate aspects like conductor sizing, the distance between electrodes, and their depth, impacting the overall effectiveness of the grounding system.

Conducting Grounding Inspection

Regular Grounding Inspection is crucial for ensuring the integrity of grounding systems. Grounding systems can degrade over time due to various factors including corrosion, physical damage, or improper installation. Inspections involve checking visible connections, measuring resistance levels, and ensuring compliance with grounding requirements.

Final Thoughts

Grounding systems are essential for the safety of electrical installations. From Equipment Grounding to ensuring compliance with Grounding Codes, every aspect plays a pivotal role in creating a safe electrical environment. For a deeper dive into grounding practices and labels, check out Clarion Safety for excellent resources.

Remember, following the best practices in grounding can save lives and prevent potential equipment damage. Always stay informed and conduct grounding installations and inspections thoroughly. For further reading on common issues and solutions regarding bonding and grounding, take a look at Safety Matters Weekly.

For more safety resources, also visit OSHA’s grounding guideline.

Posts Relacionados

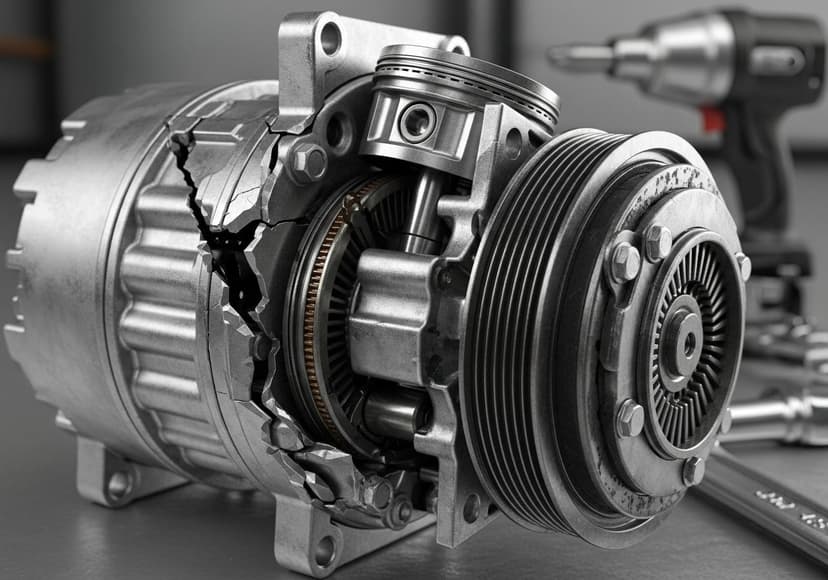

Ac Compressor Common Problems

Common issues involve refrigerant leaks, clutch failure, and internal damage impacting cooling efficiency and leading to repairs.

Ac Drain Cleaning Diy Guide

Regularly clean your AC drain to prevent clogs, maintain efficiency, and avoid potential water damage.

Ac Efficiency Maximizing Performance

Improve air conditioning efficiency by optimizing components. Achieving peak performance ensures reduced energy consumption.